- Home

- Research

- Quantum Detection

- Research results

- Cauliflower, fern, or ball? How porous platinum catches the light

Cauliflower, fern, or ball? How porous platinum catches the light

13.12.2022

Surfaces and structures of porous platinum could not be more different. Thanks to its distinctive properties and composition, the precious metal is indispensable in many fields, such as astronomy, physics, or medicine. Researchers at Leibniz IPHT are studying the chemical element and its design on a nanometer scale.

Measuring fever in the ear, exploring the weather on the Red Planet, or monitoring critical processes in industrial environments – non-contact radiation thermometers are used in a wide variety of applications. Their IR sensors, hidden inside, capture incident infrared radiation, convert it locally into heat, and generate a thermoelectric signal that scales with the temperature difference and can be measured. Thus, IR sensors make heat and temperature parameters visible. These sensors are reinforced by locally applied broadband absorber layers consisting of nanoporous platinum. This sophisticated surface finishing can support the sensitive IR sensors in the subtask of converting IR radiation into heat.

Captured light

“Non-porous platinum normally only absorbs a small proportion of the incident light, while a large part is reflected. Highly porous platinum, on the other hand, has completely different optical properties. It is very absorbent and can absorb almost all of the incident radiation. In contrast, its reflectivity, that means its ability to reflect radiation like a mirror, is extremely low,” explains Dr. Gabriel Zieger, head of the Thermal Sensors Group in the Quantum Detection Department at Leibniz IPHT.

This property makes porous platinum attractive as an optical absorber material over a broad wavelength spectrum. “Its fine structure, which can look cauliflower-like, fern- like or spherical with its different pore sizes and pore distributions under the microscope due to its elevations and depressions, increases its surface enormously. This special surface structure means that the incident radiation has hardly any chance to escape,” Gabriel Zieger continues.

Layer by layer

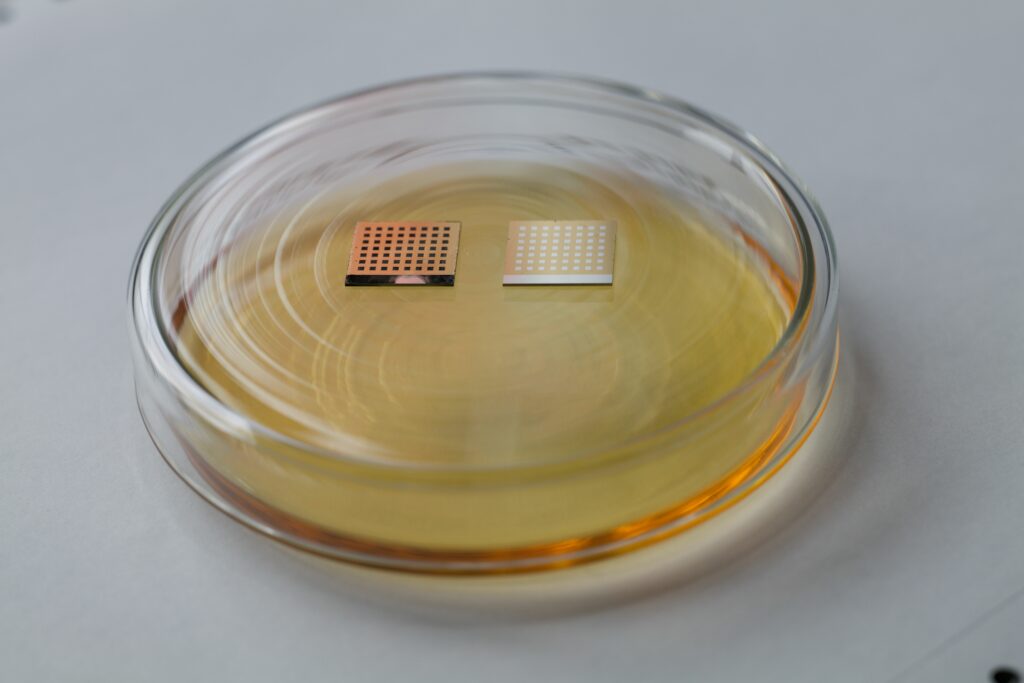

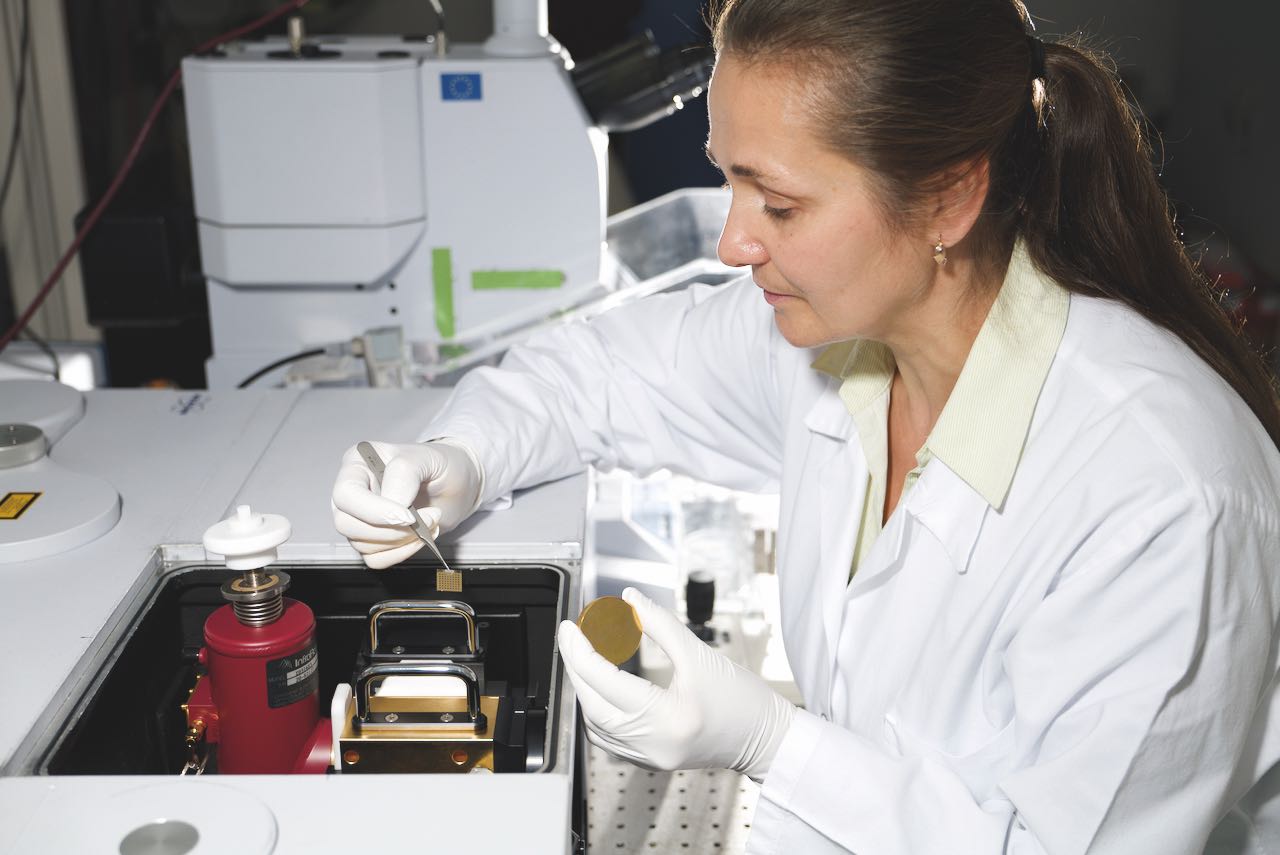

The absorption capacity of porous platinum mainly depends on its structure and thickness. To precisely control the growth of nanoporous platinum layers, researchers in Jena investigated the mechanisms behind the deposition process in 2021. “In order to electrochemically produce highly localized platinum layers, conductive patterns must first be created, for example on a substrate on which the coating is to be deposited. The coating itself takes place in an electrolytic bath containing platinum chloride. By applying an electric current, metal ions dissolve in the bath and accumulate selectively on the previously defined structures. Thus, the nanoporous platinum layer grows exactly there,” explains Dr. Sarmiza Stanca, scientist in the Thermal Sensors Group.

The researchers observed that the development of the platinum layers can be specifically manipulated: Decisive factors for the platinum layer thickness are applied voltage and electrolyte composition. An increase in temperature can also influence the electrochemical process and thus the layer thickness. Time also plays an important role, because the longer the initial material remains in the electrolyte solution, the more the platinum layer grows. Emerging hydrogen during electrolysis also influences the porosity of the platinum. “The special thing is that we can grow platinum with the help of water-free electrolysis. This is particularly advantageous for water-sensitive sensor materials, and offers great potential for optoelectronic and many other applications,” says Sarmiza Stanca.

With the knowledge gained on the precise control of platinum growth, its surface structure, porosity and thickness, even more sensitive IR sensors with optimal absorption characteristics can be created. Due to the platinum refinement, these IR sensors are able to almost completely absorb the radiation to be detected and convert it into heat, allowing to perceive even finer details.