- Home

- Technology Groups

- Competence Center for Specialty Optical Fibers

Scientific Profile

For several decades, the Leibniz-IPHT has combined research into materials and the development of technologies for the production of innovative optical glass fibers in a unique way in Europe. Great expertise and excellent infrastructural facilities in such diverse areas as material and preform production, fiber drawing, fiber functionalization, fiber and material characterization, as well as modeling and simulation have been concentrated 2021 in the Competence Center for Specialty Optical Fibers (CSF) to push new developments in the field of highly specialized glass fibers at Leibniz-IPHT and to further enhance efficiency.

| For the development and manufacturing of innovative fiber concepts, the CSF is scientifically at the forefront and actively supports all research units of the Leibniz-IPHT as well as external partners from research and industry in joint R&D projects. |

Preform development

Preforms build the base of optical glass fiber manufacturing. In the preform manufacturing our team of experienced technologists uses established processes such as for example MCVD for the deposition of ultrapure fused silica and doping elements from gaseous or vaporable precursors (rare earth elements, aluminum, germanium, phosphorus, boron). Simultaneously, alternative material and preform technologies are beeing developed and implemented to enable completely novel fiber structures and functionalities.

|

|

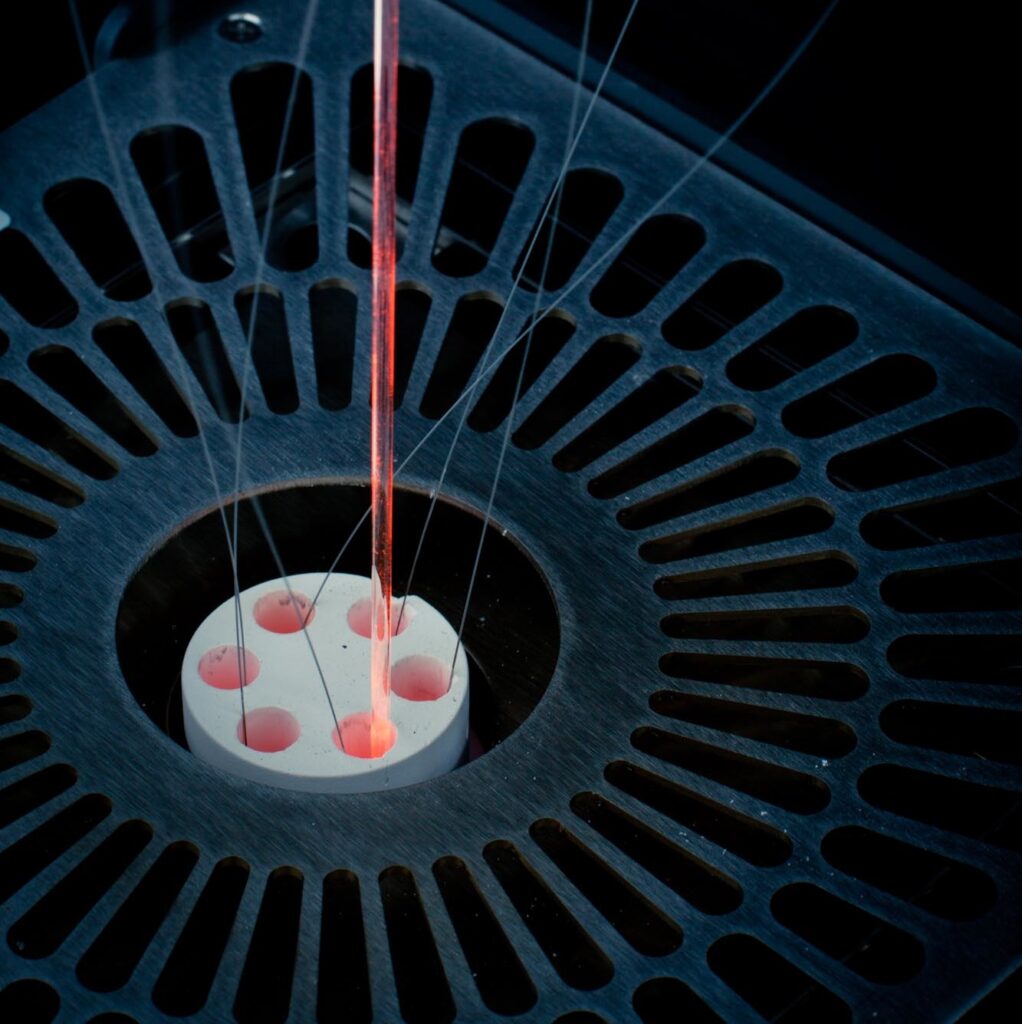

Drawing technology for highly specialized fibers, rods and canes

Modern special optical fibers have complex, often filigree internal structures or combine extreme material combinations. Years of experience and several individually optimized and adaptable fiber drawing lines qualify the specialists at the CSF at Leibniz IPHT for the manufacturing of even highly complex fibers.

|

|

Fiber-Post-Processing und functionalization

Whether for special optical fibers or simple telecommunication and data transmission fibers, whether manufactured at Leibniz-IPHT or by cooperation partners - CSF possesses and researches a variety of modification methods of existing optical fibers for subsequent implementation of outstanding photonic properties. If required, we also develop customized optical fiber-based system solutions for research and industry.

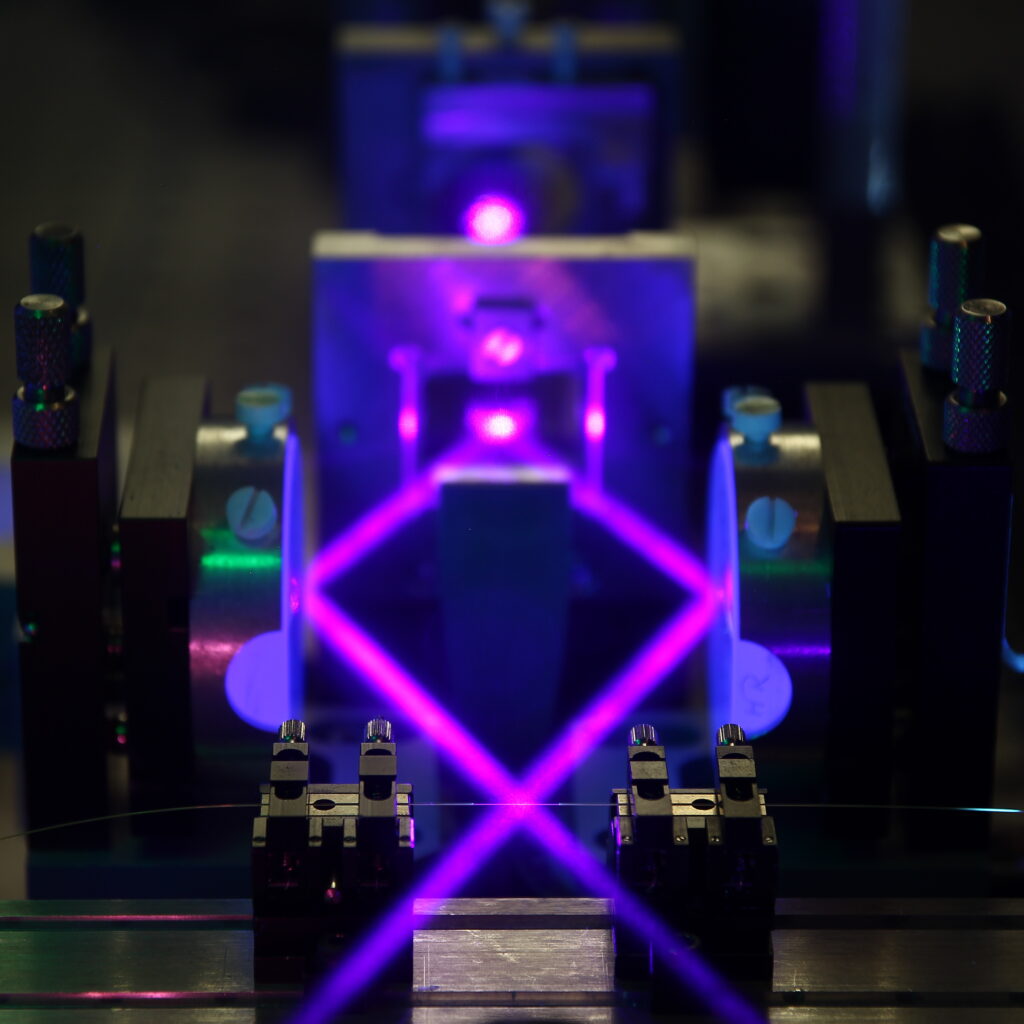

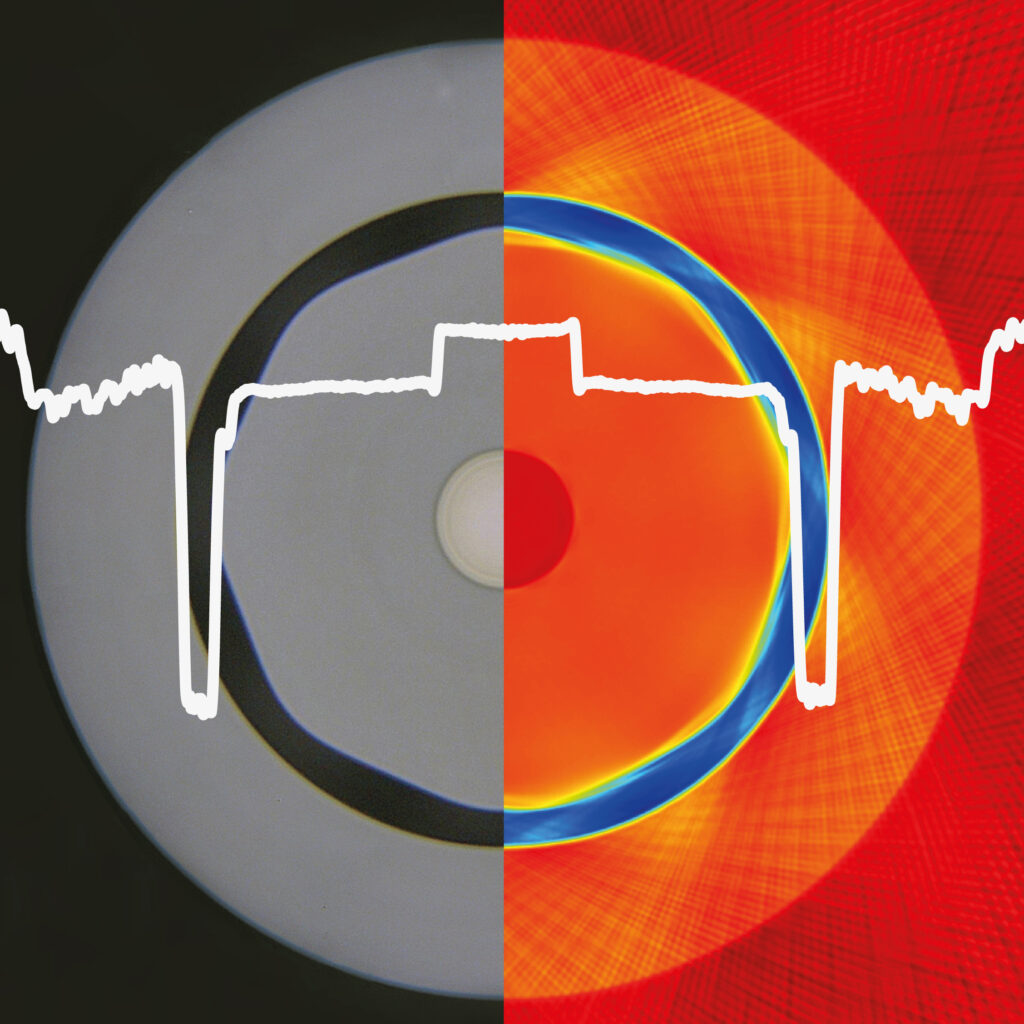

Laser-based refractive index structuring for the generation of fiber Bragg gratings (FBG) or waveguide structures

|

|

Fiber Post Processing

|

|

Fiber optic sensor systems

|

|

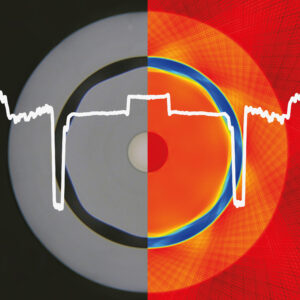

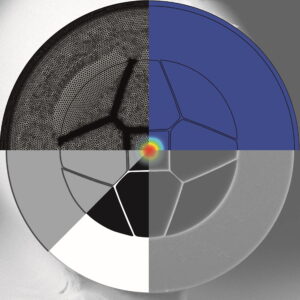

Characterization methods

Extensive characterization setups and experts with many years of experience allow for the investigation of optical and structural properties of materials, preforms and glass fibers. This ensures close support and optimization of the manufacturing processes. In addition, research groups at Leibniz-IPHT as well as external partners from industry and research, are also beeing supported.

|

|

The following complementary examinations are possible at Leibniz-IPHT as well

microstructure analysis working group of the CMNT of the Leibniz-IPHT

- Structural analysis: scanning electron microscopy (SEM)

- Chemical analysis: Electron probe micro analysis (EPMA) for determination of the concentration of chemical elements

- X-ray diffractometry

working group Optical Fiber Materials and Structures of the Leibniz-IPHT

- Thermochemical properties: differential thermal analysis (DTA) and dilatometer

- Surface characterization of powder samples (BET)

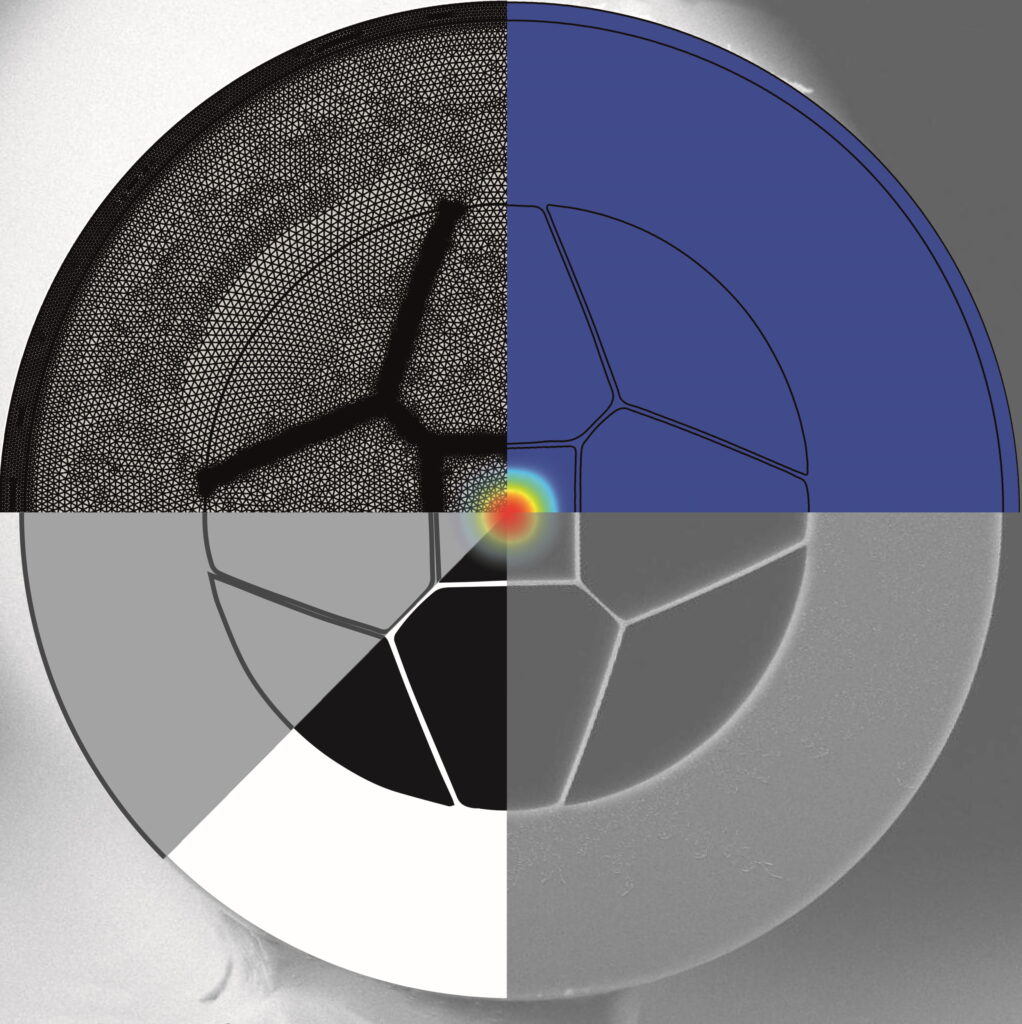

Design and simulation of specialty optical fibers

Modern optical glass fibers are often expected to have specific innovative photonic properties. To achieve this, many optical features and material parameters must be precisely calculated and harmonized with each other. Our simulation experts use optimized scripts and routines based on commercial software such as MATLAB®, COMSOL Multiphysics®, ZEMAX® and Optiwave®, but also in-house developed program libraries.

|

|

Areas of application

Fibers made in Leibniz-IPHT are used in applications in medical technology, sensors, biophotonics, quantum optics, fiber lasers, information technology / telecommunications

- Fiber laser and amplifiers (e.g. with Yb-, Er- or Tm-doping)

- Temperature and strain measurement with fiber Bragg gratings (process and infrastructural monitoring)

- Imaging (e.g. endoscopy)

- Spectroscopy (e.g. liquid and gas analysis)

- Catheters in medical technology

Research Insights

Unfortunately, this video can only be downloaded if you agree to the use of third-party cookies & scripts.

Unfortunately, this video can only be downloaded if you agree to the use of third-party cookies & scripts.

open friday [internal only]

Using this path [\\mars\usr\FA9540_KompetenzZentrumSpezialFasern\public\OpenFriday] you will find the slides of the open-friday event.