- Home

- Research

- Nanobiophotonics

- Research results

- Laboratory of the future on a chip

Laboratory of the future on a chip

19.08.2016

To further improve medical care for the populace, the laboratory of the future will be able to fit into your jacket pocket and deliver test results, such as for a blood test, within minutes. The new light-based detection methods are particularly suited to rapid onsite analysis and diagnosis. Microfluidics offers a wide range of technological solutions for combining modern spectroscopic and optical methods with a compact chip platform. Today, these microfluidic lab-on-a-chip systems (LOC) are already supplementing timeconsuming, expensive routine laboratory procedures and ensuring on-site analysis and diagnosis independent of the need for a specific laboratory infrastructure.

The clean room at Leibniz IPHT provides ideal technological conditions for the production of microfluidic components using microsystem technology. Photolithography, wet and dry etching processes, and coating methods such as sputtering are used to structure chip substrates from glass, silicon, or quartz glass. However, the tiny channels and functional components of the microfluidic chips will only form with the exact connection of both the top and bottom of a micro- or nanostructured chip by means of anodic bonding. This results in a solid chemical bond between the two halves, ensuring a high degree of stability in the finished chip. The micro- and nanotechnological processes allow for variable channel heights ranging from approximately 0.1 to 300 microns in glass and up to 800 micrometers in a triple-layer glass/silicon/glass composite system. Channels of different heights can be realized through multistage etching processes, for instance, to produce droplets in an oil-water mixture. The fine structures of free-standing nanopore arrays for nanosieves are produced by means of electron beam lithography.

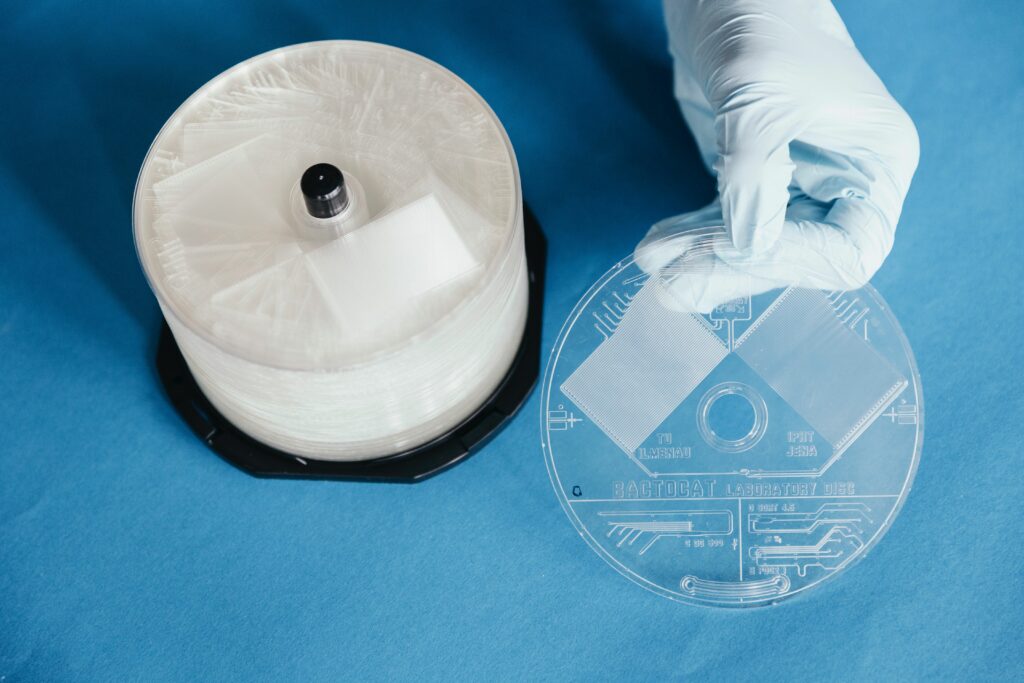

For preparation as one-way microfluidic systems made of polycarbonate, the production process incorporates the use of external service providers for DVD mass production. The format of the microfluidic laboratory disc derived from the DVD standard provides sufficient space for complex screening applications such as the parallel generation, processing, and examination of up to 5,000 individual sample drops.

The geometry masters for producing these discs with the necessary microstructures are created in the Leibniz IPHT clean room and provide the master for the production of the half-discs through one of the world‘s leading service providers for DVD mass production. The subsequent aligned bonding of the two microstructured DVD half-discs into the final microfluidic system is again performed in the Leibniz IPHT clean room. This reduces pure production costs to less than 100 euros per component for the one-way microfluidic systems.

For the successful implementation of ideas from research and industry, Leibniz IPHT bundles competencies in the areas of microsystem technology, microfluid mechanics, photonics, and automation. The researchers use an efficient design approach to deliver customized, highly integrated microfluidic systems for a variety of applications. Microfluidic functional elements with versatile combination potential are used In addition to standardized chip formats and fluid connection technology. This enables complex process sequences to run on a single chip that can be implemented in optical measurement systems. At the same time, the chip design benefits from the software-based modeling of these microfluidic networks. With in silico modeling, the interaction of the microfluidic functional elements in single-phase flow systems and drop-based systems can be analyzed and visualized even before the chip is produced. In this way, potential design errors are recognized prior to production, and the functionality required for the chip is often already achieved in the first development life cycle.

What is microfluidics?

Small amounts of fluid in a confined space obey a different set of physical laws than those that govern macrofluidic systems. A large surface-to-volume ratio, capillary forces, and a weak turbulent flow dominate the behavior of fluids in ducts a few micrometers in diameter. These effects are used in a targeted manner to completely mix two fluids in less than a millisecond. For other applications, cells are separated from a cell suspension and then sorted, rotated, and analyzed by optical spectroscopic methods through the targeted selection and fluidic interconnection of functional elements in the microchannels – all using only a few drops of a sample on a postcard- sized chip (16 x 12.5mm2).