- Home

- Technology Groups

- Competence Center for Micro- and Nanotechnologies

- Research results

- Crisis Helpers

Crisis Helpers

12.05.2021

Sensors from Leibniz IPHT fly to planets and celestial bodies. In the Corona crisis, they are needed on Earth: as life-saving technology in ventilators

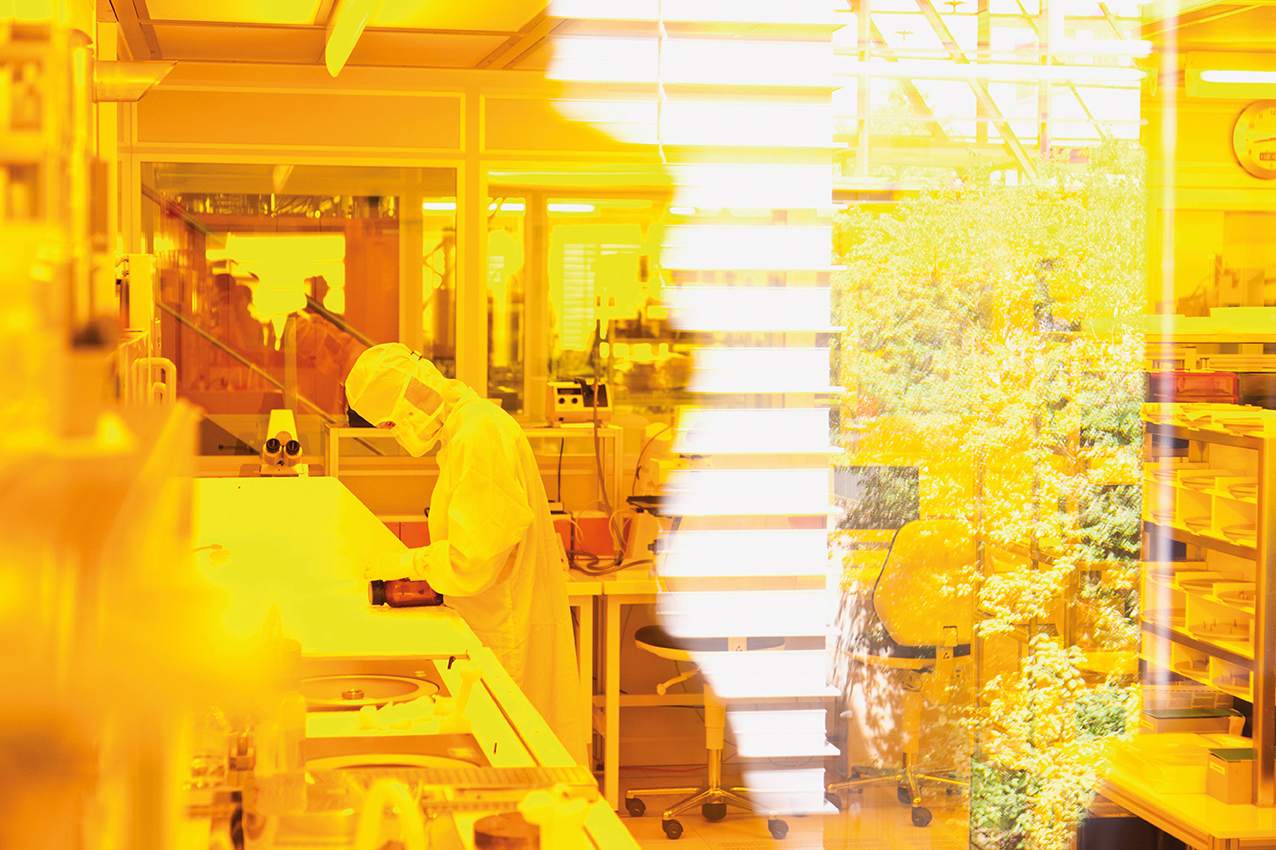

It was March 2020 when the effects of the global pandemic arrived in the clean room of Leibniz IPHT. “We have to ramp up production, at least by double,” was the motto among the IR sensor manufacturing team. The more the novel coronavirus spread around the world, the more urgently the sensors were needed, which the employees of the Competence Center for Micro- and Nanotechnologies manufacture.

The IR sensors are a basic component in ventilators sold by the U.S. corporation General Electric to intensive care units and hospitals around the world. Demand was growing as infection rates skyrocketed. At this point, the USA alone had already requested a hundred thousand additional devices. To this, they need the support from Jena and Hermsdorf, where the technology company Micro-Hybrid Electronic GmbH builds the sensors from Leibniz IPHT into a module.

Measure how much air the patient gets

“Our scientists have further developed and optimized the infrared sensors over many years so that today they are among the best in the world,” explains Jürgen Popp, scientific director of Leibniz IPHT. The Jena sensors are regularly on board of space missions, most recently to Mars and Mercury. Their readings from there provide information about the weather on Mars and contribute to gaining insights into the formation of the planet.

The technical principle is the same, whether in space or in intensive care. The sensors measure the incoming infrared radiation. Converted, this reveals both what the temperature of a body is – a planet, for example – and how a patient is doing. “The ventilators have an infrared light source,” explains Kay Dietrich, who heads the research group that makes the IR sensors. “Their light shines into a chamber where the patient’s breathing gas circulates. At the other end of the chamber, the sensor measures the amount of incoming infrared light. The higher the CO2 concentration in the breathing air, the more infrared light is absorbed. From the change in the amount of light that makes it to the sensor, the amount of CO2 in the breathing air is calculated.” This lets doctors know how high the respiratory rate is and how well the oxygen supply through the lungs into the blood is working.

Double shifts at Easter

In the middle of the first lockdown, the two dozen or so employees in sensor production are working at full speed: double shifts into the evening hours and on weekends. Even at Easter, operations continue. They are battling against corona-related supply bottlenecks for substrates and mastering the challenge of balancing family and career in view of closed schools and kindergartens. They are converting their system and producing more than twice as many sensors as before. “A great achievement,” Jürgen Popp emphasizes. “I would like to thank our employees very much for this. We can be proud that we can continue to support our partners so well even in this state of emergency.”