- Home

- Research

- Quantum Detection

- Research results

- Interference-enhanced Raman Spectroscopy for the Detection of Surface Functionalization

Interference-enhanced Raman Spectroscopy for the Detection of Surface Functionalization

28.03.2019

An aluminum oxide coating makes it possible to detect biomolecules sensitively and non-destructively on Raman-compatible chips. This is particularly important in the production of substrates for sample preparation because this constitutes an instrument for quality control; therefore, only quality chips can be selected for further experiments.

By A. Pahlow // K. Weber

Raman spectroscopy is a versatile instrument for the characterization of samples from various fields of application. The resulting spectra contain highly specific information about the molecular composition of the investigated substances. Among other things, this can be used to identify bacteria, which is a central concern in the diagnosis of infectious diseases. In addition, the necessary spectra can be recorded within a few minutes. Therefore, this spectroscopic detection approach is extremely attractive because the rapid identification of the pathogens enables a rapid start in treatment, which can save the lives of seriously ill patients.

When examining medical samples, however, the bacteria to be identified are hidden in a more-or-less complex matrix because bodily fluids such as saliva, urine, and blood must be examined. In order to perform a successful Raman-based detection of the bacterial cells, they must first be isolated from the sample matrix.

For this purpose, biofunctionalized metal surfaces can be used, for example. Metal surfaces are suitable because they do not provide an interfering background signal during Raman measurement of the cells. During biofunctionalization, so-called capture molecules for the bacteria are applied to the metal surface so that the bacteria in the sample fluid adhere to it. Subsequently, the corresponding chip substrates are washed to remove any unwanted sample components that may have bound nonspecifically to the surface.

The production of such chips for sample preparation is carried out in several steps and is a process that is not always easy to control. First, the metal surface must be modified with an organosilane to create reactive groups for the covalent binding of capture molecules. This method exploits the fact that some metals form an oxide layer in air, making hydroxyl groups available for silanization. Subsequently, capture molecules for bacteria (e.g., antibodies and siderophores) can be stably anchored to the metal surface. Both the detection of chemical functionalization with a silane and the detection of biological functionalization with a capture molecule is usually time-consuming or results in the destruction of the investigated substrate. This was our motivation to develop an alternative method.

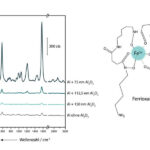

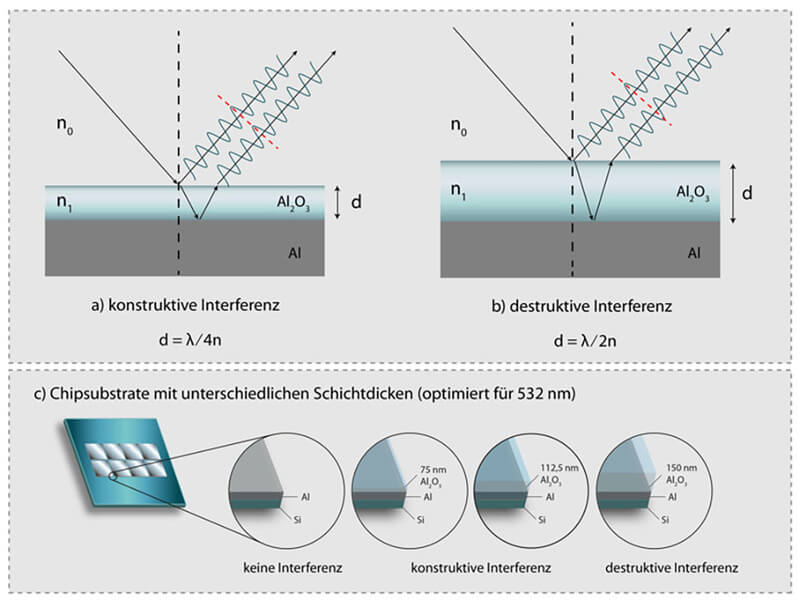

Our tried and tested Raman chip substrates are manufactured from silicon wafers onto which aluminum measuring fields are applied by means of cathode sputtering. In order to analyze the following modifications using Raman spectroscopy, we further coated the chips with aluminum oxide. It is important that the aluminum layer have a certain thickness, the specific value of which depends on the excitation wavelength used in the later Raman spectroscopic investigation. Depending on the thickness of the layer, the signal is amplified or attenuated when monochromatic light is irradiated. The underlying physical principle is shown schematically in Figure 1. When the laser light hits the aluminum oxide layer, one part is reflected while the other part is refracted and passes the layer until it hits the aluminum mirror and is reflected there. When it exits the aluminum oxide layer, both parts overlap, which is referred to as interference. Depending on the path difference (i.e., the difference in the distance travelled), the amplitude is either attenuated or amplified. In this way, the Raman signal of the molecules directly anchored to the aluminum oxide layer can also be amplified or attenuated. We have successfully demonstrated this for the siderophore ferrioxamine B, which is a promising candidate for the isolation of various pathogenic bacteria. Figure 2 shows spectra of the siderophore that are measured on substrates with aluminum oxide layers of different thicknesses and an uncoated aluminum chip. Since we performed the measurements with an excitation wavelength of 532 nm, layer thicknesses of 75 nm result in amplification, while 150 nm of aluminum oxide almost erase the signal. A layer thickness of 112 nm has only a slightly amplifying effect on the Raman signal intensity.

With these results, we have succeeded for the first time in using interference-enhanced Raman spectroscopy for the detection of biomolecules. The novel chip substrates enable us to test whether functionalization with the capture molecules was actually successful before they are applied in isolation experiments for bacteria. The same spectrometer can be used for this quality control as for the investigation of the bacteria, so that no additional costs arise for the purchase of an additional measuring device.

Funded by: BMBF