- Home

- Research

- Fiber Research and Technology

- Research results

- Tapered Fiber Amplifiers Prepared by Powder Sintering Technology for Peak Power Scaling and Beam Quality Improvement

Tapered Fiber Amplifiers Prepared by Powder Sintering Technology for Peak Power Scaling and Beam Quality Improvement

12.04.2018

The use of short local tapers in large mode area fiber amplifiers is proposed for peak power

scaling while maintaining good beam quality. To avoid modal distortions, the powder sintering technology (REPUSIL) was employed to obtain core materials with excellent refractive index homogeneity. High peak powers of more than 500 kW with 1.4 mJ of energy for untapered rod-type fibers and 230 kW for tapered fibers were achieved. The beam quality could be significantly improved from an M2 value of approximately 10 to 3.5.

By: Martin Leich // Yuan Zhu // Tina Eschrich // Stephan Grimm // Jens Kobelke // Hartmut Bartelt // Matthias Jäger

Fiber lasers and amplifiers are currently used in a wide variety of applications in the research fields of material processing, spectroscopy, sensor technology, and medical technology. Due to its high beam quality and power density, the fiber laser is already used in numerous applications in industrial manufacturing (e.g., automobile production). Particular challenges are posed to a laser in remote processes, with which, for example, the structuring or functionalization of large surfaces of different materials (e.g., metal or solar modules) is to be carried out very quickly and efficiently. The European joint project SurLas (M-Eranet, funded by the BMBF) is dedicated to this topic. A new type of ps fiber laser source is to be developed, which is suitable for highly efficient industrial production processes. It must, therefore, be robust, generate ultrafast pulses at very high peak power and beam quality, and be cost effective. The core component of this source (and the fiber amplifier) is an ytterbium-doped laser fiber, which is to be implemented using the reactive powder sintering process (REPUSIL) developed at IPHT in cooperation with Heraeus Quarzglas.

In order to achieve very high peak power levels in a fiber laser, non-linear processes (especially Raman scattering) and optical limits (e.g., damage threshold of the glass) have to be suppressed. Our concept is mainly based on the enlargement of the core diameter and the area of the active fiber’s mode field, which reduces the laser intensity and thus the non-linear processes. An additional reduction in non-linearity is achieved by using very short fiber lengths (approx. 0.5 m to 0.8 m), which requires a high gain and, therefore, rare-earth doping and a special fiber design with a high core/cladding ratio. In order to implement a cost-effective and robust beam source in this way, Yb-doped large-core step-index fibers are being developed. The REPUSIL technology is perfectly suited for the required homogeneity of the refractive index profile.

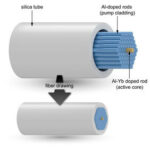

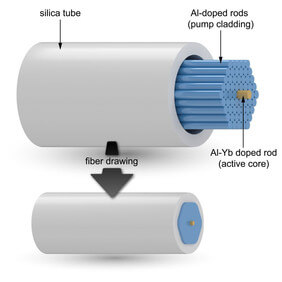

Figure 1 shows a schematic of the production of a fiber preform by “stack and draw” – the stacking of glass rods in the desired arrangement and subsequent fusion during fiber drawing. For this purpose, REPUSIL fused silica with a very high co-doping of ytterbium (0.6 mol% Yb2O3) and aluminum was used for the core rod while rods with a high aluminum concentration (0.8 mol% Al2O3) were used for the pump cladding. When the doping is selected, both the gain and the refractive index profile of the fiber are simultaneously chosen.

Due to the large core diameter and the relatively high numerical aperture of the core (NA=0.15), the fibers are highly multimodal. In order to achieve a high beam quality from this fiber, it is necessary to excite and amplify its fundamental mode. For this purpose, a short adiabatic taper was developed during the project, in which the laser fiber is tapered by a factor of 9 to a core diameter of 6.4 µm within a length of 5 cm. This taper is excited within a multistage amplifier setup (MOPA) by a fundamental-mode short-pulse signal (seed). Within the active large-core fiber (56 µm core) the signal is then amplified to a peak power of 230 kW (0.5 mJ of pulse energy).

Figure 2 shows the measured beam quality (figure of merit M2) after signal amplification in an untapered fiber (inset) and a tapered fiber. While an average value of M2≈10 was obtained across the investigated power range in the untapered fiber, a significant improvement was achieved by the tapered amplifier with M2≈3.5. Thus, the concept of the adiabatic taper for improving beam quality and robust signal coupling was successfully demonstrated.

A further objective of research is the production of fibers with lower core NA and improved material homogeneity with the aim of achieving very high peak power levels at almost diffraction-limited beam quality with M2<1.3.

Funded by: BMBF, China Scholarship Council.